stainless steel and plastic solenoid valves: a comprehensive overview with meishuo’s excellence

Release time:2025-04-22 19:19:45

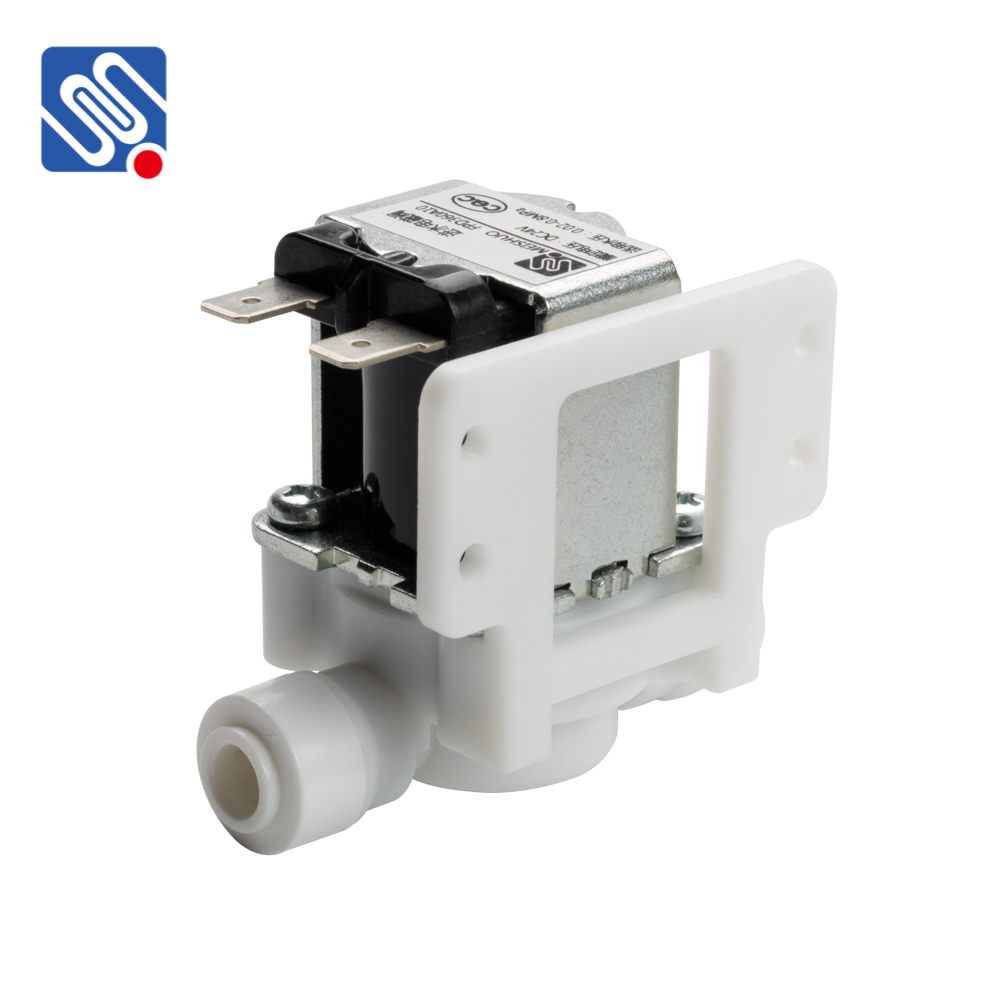

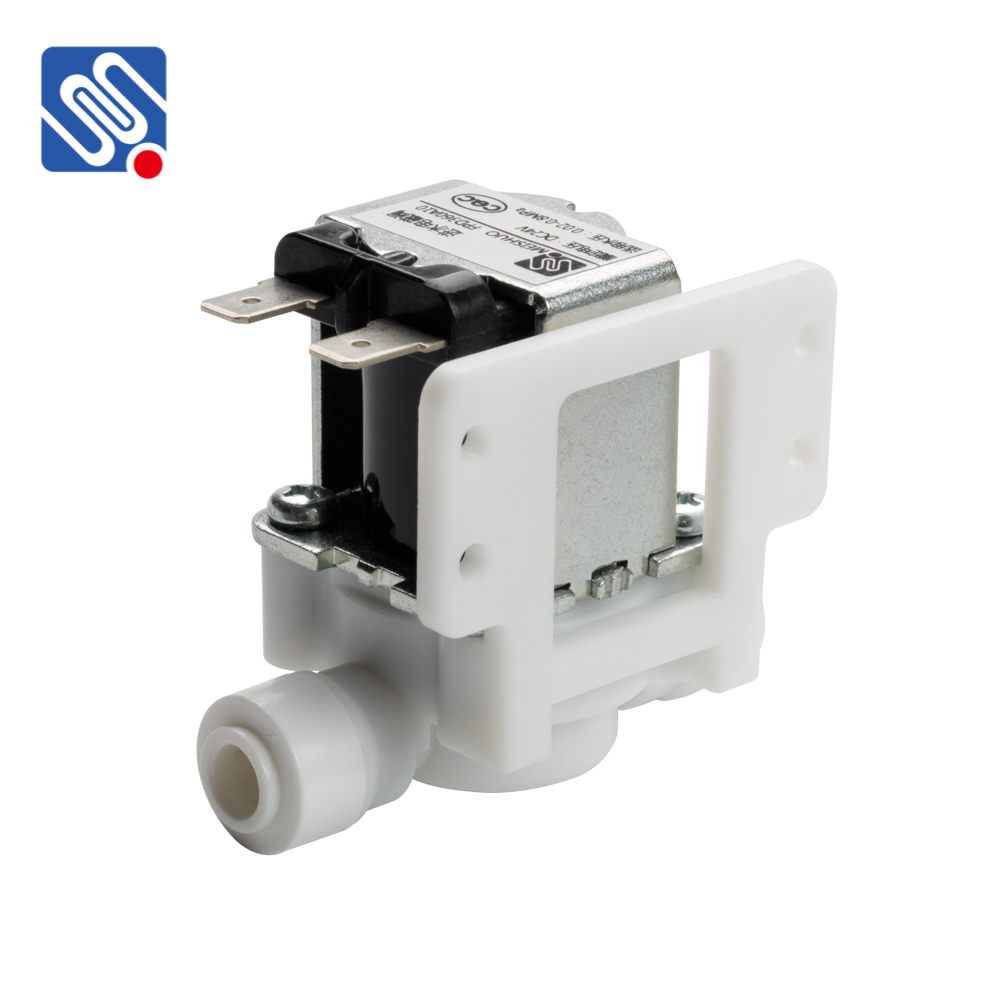

In modern fluid control systems, solenoid valves play a pivotal role in regulating the flow of liquids and gases. These valves use an electromagnetic coil to operate a valve mechanism, ensuring precise control over the movement of fluid through pipes or channels. Among the various materials used for manufacturing solenoid valves, stainless steel and plastic are two of the most commonly employed. Both materials offer distinct advantages depending on the application, and companies like Meishuo have made significant strides in producing high-quality solenoid valves that meet diverse industry needs.

Stainless Steel Solenoid Valves: Durability and Resistance

Stainless steel solenoid valves are known for their robust construction, resistance to corrosion, and ability to withstand high temperatures and pressures. Stainless steel is a versatile material, capable of enduring harsh environments, including those exposed to chemicals, oils, and gases. This makes stainless steel solenoid valves ideal for industries such as chemical processing, oil and gas, and automotive manufacturing, where high performance and reliability are crucial.

One of the key benefits of stainless steel solenoid valves is their longevity. Unlike plastic, which may degrade over time due to exposure to chemicals or extreme conditions, stainless steel provides a more durable and long-lasting solution. Moreover, stainless steel solenoid valves are often used in high-pressure systems because of the material's strength and ability to handle greater stress.