understanding the functionality and applications of flow control solenoid valve

Release time:2025-10-19 11:32:11

Flow Control Solenoid Valves (FCSVs) are essential components in a variety of automated systems, playing a pivotal role in regulating the flow of fluids such as gases or liquids. These valves utilize electromagnetic technology to precisely control fluid flow, making them indispensable in industries ranging from automotive to manufacturing. In this article, we will explore the basic working principle, types, applications, and benefits of Flow Control Solenoid Valves, providing a comprehensive understanding of their importance in modern automation.

Working Principle of Flow Control Solenoid Valve

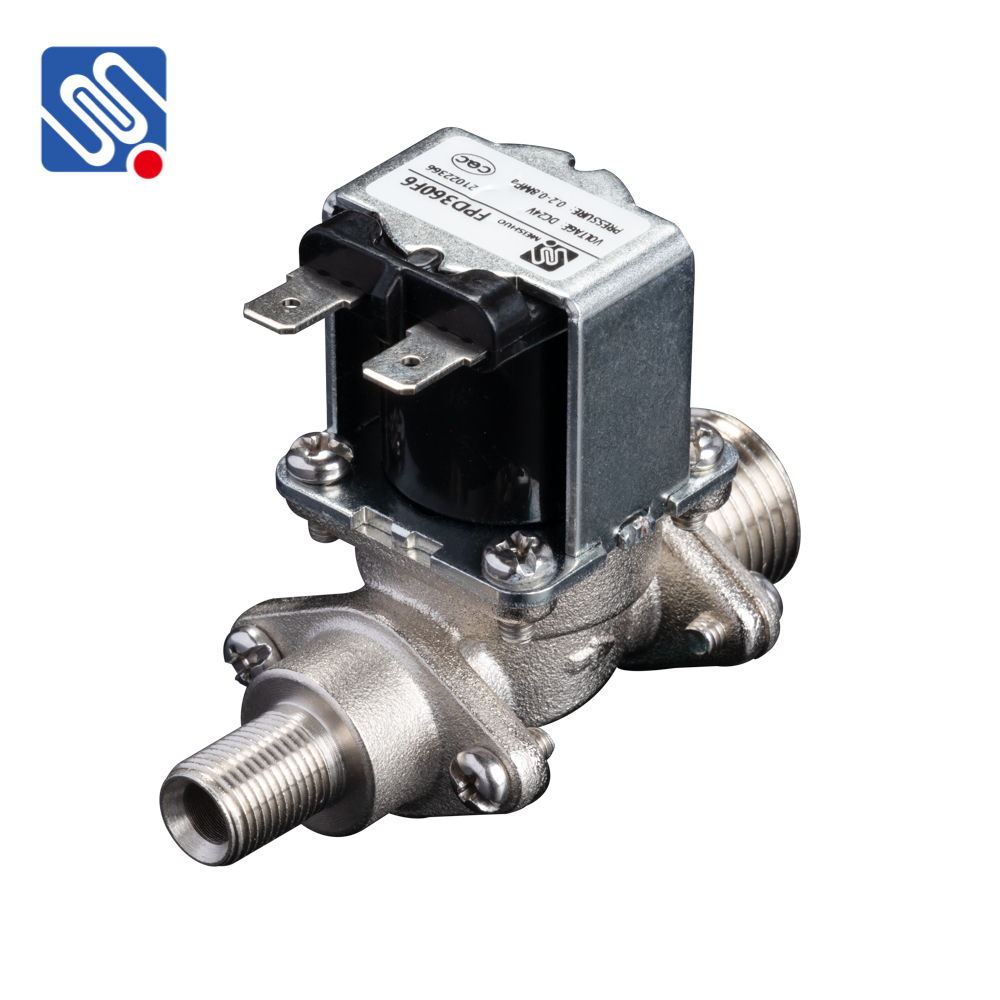

At the core of a Flow Control Solenoid Valve is an electromagnetic actuator, which is responsible for controlling the flow of fluid through the valve. The valve typically consists of a solenoid coil, a movable plunger or armature, and a valve body. When an electrical current is passed through the solenoid coil, it generates a magnetic field that pulls or pushes the plunger. This movement either opens or closes the valve's orifice, thereby regulating the fluid flow.

What distinguishes the Flow Control Solenoid Valve from other types of solenoid valves is its ability to regulate the flow rate continuously. The flow rate is adjusted by controlling the opening size of the valve, which is proportional to the electrical signal (usually in the form of current or voltage) applied to the solenoid. This precise regulation allows for applications that require fine control over fluid flow, such as in hydraulic or pneumatic systems.